Back to the Madison Ross Media Group homepage

|

Turbochargers and Superchargers are all about making power, but most don't know how this occurs. The key to comprehension lies in grasping the most basic thing about any internal combustion engine: the fact that it is basically an air pump. The pistons create NEGATIVE pressure, or vacuum, as they go down--which sucks in air at atmospheric pressure. The air is combined with gasoline inside the cylinders and ignited by the spark plugs. The resultant explosion forces the piston down--and it is that motion, ultimately, that turns the wheels that drive the car. |

| If you can get a mental handle on that, you'll see that getting more air and fuel into the engine would make for a bigger, more powerful explosion. The car would go faster when you floored it. Here's where turbos and superchargers come in. Both are mechanical compressors that force additional air into the engine under POSITIVE pressure--which is called "boost." They make small engines produce big engine power--and make big engines more fun. |

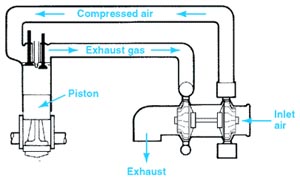

| Functionally, the difference between a turbo and a supercharger is in the means by which they are driven. A turbocharger ("hair-dryer" to gearheads) is powered by spent exhaust gases, which are used to spin a paddle-wheel-like part called an impeller. The impeller is connected on a shaft to the turbine, which has vanes on it (picture a paddle wheel and you'll get the idea) to compress the incoming air, thereby creating boost, or pressurized induction. A wastegate is built into The system to prevent over-pressurization by |

|

| venting the exhaust gases away from the

impeller. Usually, the turbocharger will be lubricated by pressurized oil--critically

important as the impeller/turbine assembly can spin at speeds in excess of 100,000

rotations per minute (RPM).

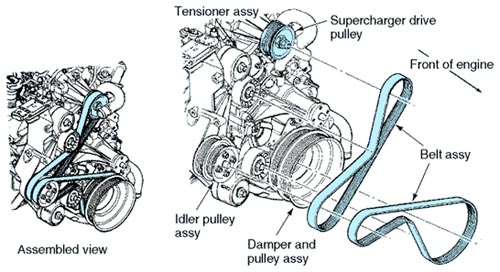

A supercharger, in contrast, is driven by an accessory belt--much like the alternator, air conditioner compressor, and water pump. Internally, there are two (sometimes three) lobes that rotate, sucking in the air and force-feeding it to the engine. The supercharger makes a very distinctive noise, which can be music to the ears of performance enthusiasts.

|

|

Turbos and superchargers are not recent developments; both have been around since at least the 1930s, and both have their strong and weak points. The No. 1 advantage of the supercharger is that it does not suffer "lag"--a term used to describe the moment's hesitation between the time the driver floors the gas pedal and the time the engine responds. Turbocharged engines often suffer from lag because it takes a second or so for the exhaust gases that drive the impeller/turbine to reach sufficient velocity before boost is created. For a second or so, the engine feels sluggish and weak--then it comes alive like a scalded dog as the turbo "spools up." This is not a problem with a supercharger because the "blower," as superchargers have been nicknamed, is belt-driven and therefore responds immediately as the driver revs the engine--creating boost whenever the gas pedal is mashed.

Modern turbocharged engines are much better than the turbocharged engines of the past, such as the old Chevy Corvair Spyder, because of the switch from carburetors to fuel injection--and the adoption of electronic engine controls. Lag is not nearly the problem it once was--though it hasn't been eliminated entirely. But the driveability problems of older turbocharged engines (hard starting, poor cold-weather performance, etc.) are mostly gone. Some manufacturers have sought to address the problem of turbo lag by using two smaller, sequential turbochargers rather than one large unit. The smaller turbos spool-up faster because there is less inertia to overcome, yet they deliver the same punch, together, at full-boost, as a single large turbo. The 1999 Volvo S80 T6 uses twin-turbos in this way, as does the Mitsubishi 3000GT VR-4.

Superchargers tend to have one other advantage over turbos. In addition to not having a problem with "turbo lag," superchargers, as a system, are less complex than turbos, which require extensive modification of the exhaust system, among other things. The supercharger, in contrast, is simply bolted to the top of the engine (conventional Roots-style) or mounted off to the side (Whipple and Vortec). They are thus cheaper to install and generally cost less to service and maintain. A pulley on the supercharger's snout is driven by an accessory belt and sometimes the hood must be modified for clearance--also true with turbocharged engines.

General Motors has made extensive and successful use of superchargers as a power booster for the 3.8 liter V-6 engine, which now develops 240-horsepower in the Buick Regal and Park Avenue Ultra, as well as the Pontiac Grand Prix and Bonneville.

A "negative" shared by both types of forced-induction systems (turbos and superchargers) is the higher operating temperatures they create--and the added strain placed on the engine itself from these higher temperatures and from the stress of being operated under "boost." Usually, these factors are taken into account when the manufacturers design an engine intended for supercharged or turbocharged use--and special, heavy-duty components are specified. Nonetheless, regular oil changes and extra vigilance keeping an eye on the temperature gauge are definitely called for.

With turbocharged cars, it is a very good idea to let the engine idle for a moment or two (30 seconds) before turning the key to the "off" position and shutting the engine down, especially after the car has been driven hard. By following this recommendation, you are letting vital lubricating oil cool down the white-hot turbo. Sludge deposits will be kept at bay and your turbo will live a long and happy life.

No such "shut-down" procedure is necessary with a supercharged engine because it is not lubricated by engine oil; typically, there are sealed, pre-lubed bearings that are designed to last for the life of the unit. What IS important with a supercharged engine (and a turbocharged one, too) if you want it to last, is to be gentle with it during warm-up. That means no full-throttle starts for at least the first 10-15 minutes of operation. Blasting the gas with a cold engine is bad for any car, but the pressure generated by turbochargers and superchargers only exacerbates the potential for premature failure if you dog it before the oil gets warm and the bearings and other vital innards reach normal operating temperature.

That's it for now. Hopefully this article has helped somewhat in your decision on getting a turbo or a blower, or has at least taught you something that you did not know beforehand.

Note: The information

in this article was compiled from various sources on the internet and

have been deemed to be 100% correct. If you notice any errors please inform MW98GT.